What is the application of MINGDA 3D printers in ventilators?

In recent years, news stories about 3D printing medical equipment have emerged around the world, and the application potential of 3D printing in the medical field is constantly being confirmed. There is no doubt that 3D printing is gradually penetrated into all aspects of the medical industry.

From 2020 to now, the growing demand for ventilators due to the global outbreak of Covid-19 has driven the accelerated production of new products by medical device manufacturers.

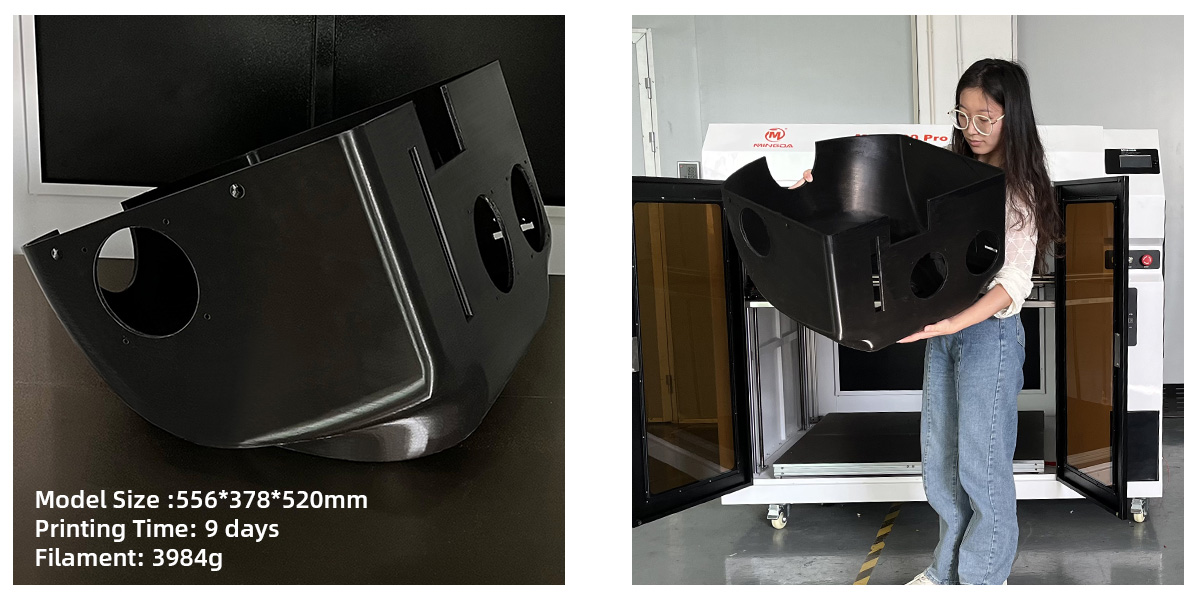

Recently, a well-known Hungarian medical equipment manufacturer chose MINGDA MD-1000 Pro because it needed to use 3D printing technology to print a ventilator shell model in the new product development stage.

The above video is showing that the MINGDA MD-1000 Pro 3D printing ventilator case model.

Because the model needs to be tested for structure and weight, there are certain requirements for the hardness of the printing material, so MINGDA choose HtPA-GF to print, The properties of the HtPA-GF is low moisture absorption, high strength and good wear resistance.

HtPA-GF is the material of choice for many users in the medical device industry to print outer casing. The printing temperature of HtPA-GF needs to be as high as 300-320°, while the nozzle temperature of common FDM 3D printers on the market can only reach 250°. In view of the needs of medical equipment users, MINGDA's high-temperature 3D printer MD-1000 Pro has a maximum nozzle temperature of 350°, which can print a variety of high-temperature materials, such as PET-GF, PET-CF, PA12-CF, PA12-GF, HtPA-GF, HtPA-CF, etc., not only can be used in the medical equipment industry, but also in industrial equipment, automotive Auto parts, etc.

Related News

Contact US

Product Information

Quantity

Unit

Piece

Support order samples, customization, wholesale direct, and complete payment. If the product you look for does not have corresponding customized content, pls fill out the form below to contact us, and we will reply ASAP.