Emerging material PPS-CF10: Can it spark a new material revolution across various application fields?

In numerous industrial sectors, many key components are required to operate stably for long periods in complex environments involving high temperatures, high loads, and corrosion, imposing extremely high demands on the comprehensive performance of materials. Carbon fiber-reinforced polyphenylene sulfide (PPS-CF10) composite material, with its unique combination of properties, demonstrates significant advantages in special working conditions across multiple industries and has become an ideal solution for addressing various material application challenges.

Stringent Requirements of Industrial Environments on Materials

The modern industrial production environment is increasingly complex and diverse, leading to ever-stricter performance requirements for materials. In terms of high-temperature environments—such as automotive engine compartments and heat dissipation areas of electronic equipment—temperatures often reach 150-250°C, where ordinary materials are prone to thermal deformation and performance degradation. Regarding mechanical properties, components like transmission parts and structural supports need to withstand high loads and friction, demanding high strength and wear resistance from materials. Meanwhile, in scenarios involving contact with chemical media (e.g., chemical pipeline connectors and food processing equipment parts), materials must also exhibit excellent corrosion resistance.

Traditional materials often fall short when facing these complex working conditions. For instance, ordinary plastics tend to soften and deform at high temperatures, failing to meet structural stability requirements. Although metal materials have high strength, they are heavy, susceptible to corrosion, and involve high processing costs. Some composite materials excel in a single performance aspect but struggle to balance overall performance.

Analysis of Performance Advantages of PPS-CF10 Composites

By incorporating 10% carbon fiber reinforcement into the polyphenylene sulfide matrix (PPS), PPS-CF10 composites achieve comprehensive optimization of material properties, enabling them to effectively meet the challenges of the aforementioned industrial environments.

1. Excellent High-Temperature Resistance

PPS-CF10 exhibits outstanding high-temperature resistance, with a continuous service temperature of up to 200°C and the ability to withstand short-term temperatures of 260°C. In high-temperature environments, the material maintains good mechanical properties and dimensional stability, without significant deformation or performance degradation due to temperature changes. This characteristic allows it to operate stably under high-temperature working conditions, meeting the needs of applications such as engine peripheral components and high-temperature pipeline fittings.

2. Superior Mechanical Properties

The addition of carbon fiber significantly enhances the mechanical properties of PPS-CF10. Its tensile strength reaches approximately 60MPa, and its flexural strength is around 95MPa, providing good rigidity and a certain degree of toughness. The notched Charpy impact strength is about 5kJ/m², while the unnotched Charpy impact strength can reach 11kJ/m², demonstrating excellent impact resistance. Additionally, the material has a Young’s modulus of approximately 5400MPa and a flexural modulus of around 4600MPa, ensuring excellent structural stability. Combined with its low friction coefficient and good wear resistance, it can withstand long-term friction and loads, making it suitable for manufacturing various transmission components and structural supports.

3. Good Chemical Corrosion Resistance

PPS-CF10 inherits the excellent chemical corrosion resistance of the PPS matrix, exhibiting strong resistance to acids, alkalis, salts, and various organic solvents. In environments exposed to different chemical media, the material is less prone to corrosion, aging, or other deterioration, maintaining stable performance over the long term and extending the service life of components.

Industry Application Cases of PPS-CF10

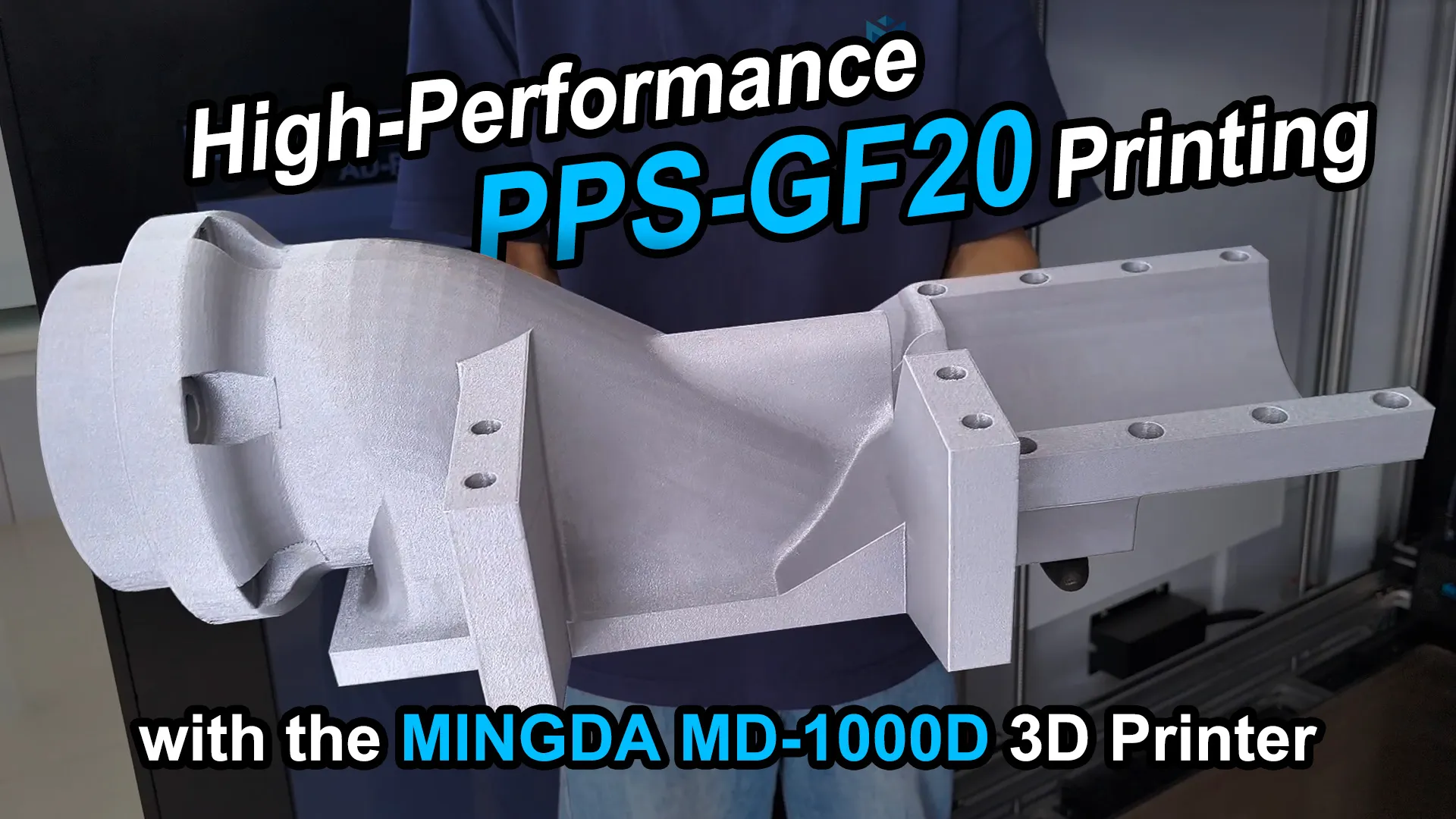

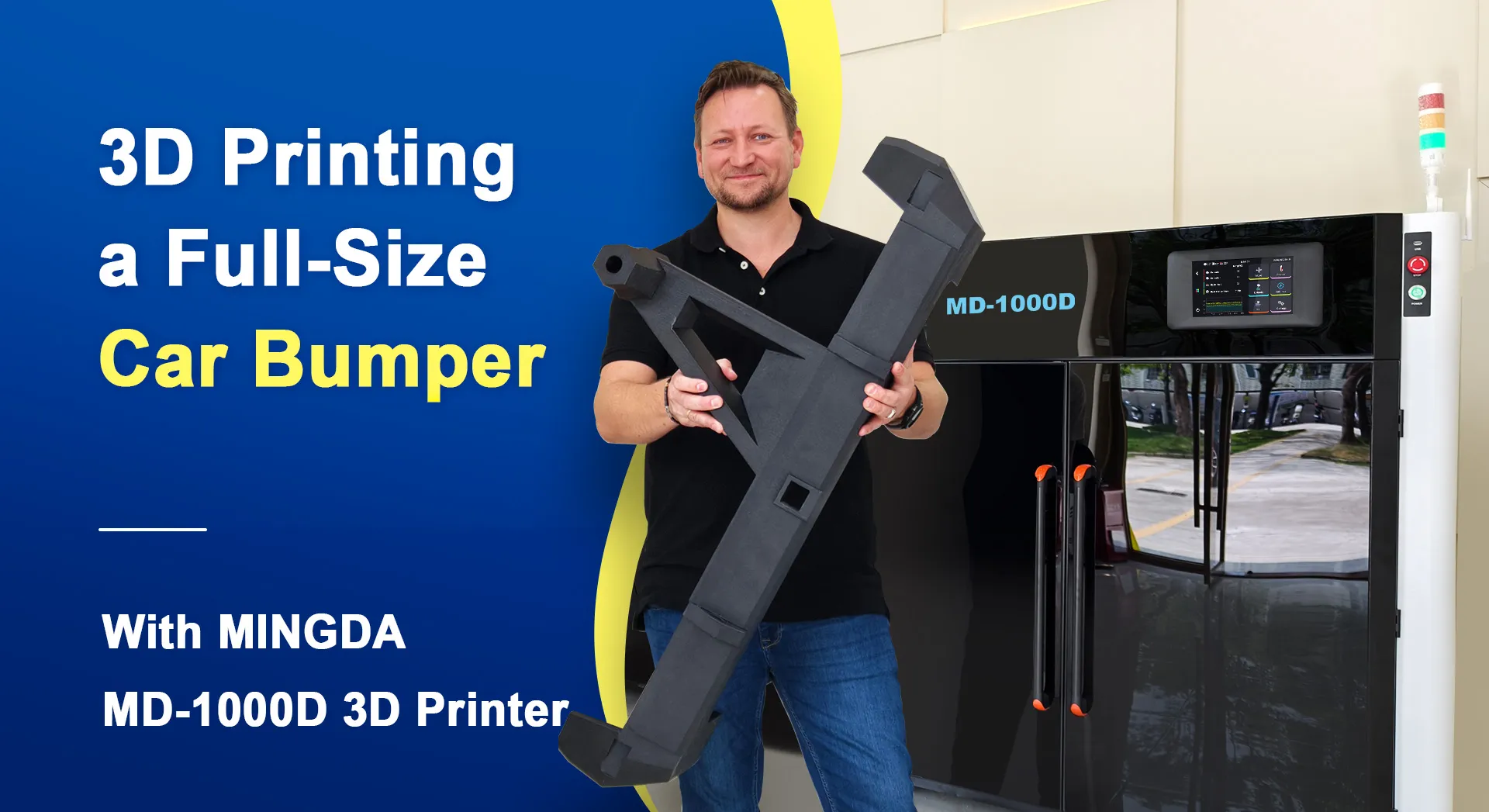

1. Automotive Industry: Transmission System Components

In automotive transmission systems, the shift fork of a certain vehicle model endures high impact forces and friction for extended periods, while operating in a high-temperature environment. After adopting PPS-CF10 for shift fork manufacturing, the weight is reduced by 30% compared to traditional metal shift forks, lowering vehicle energy consumption. Moreover, its excellent wear resistance extends the service life to more than twice that of metal shift forks. At the same time, the material’s high-temperature resistance ensures the shift fork does not deform in the high-temperature engine compartment, guaranteeing precise and reliable shifting.

2. Electronic and Electrical Industry: Connector Housings

Connector housings in electronic equipment require good insulation, high-temperature resistance, and mechanical strength to protect internal circuits from external environmental influences. Connector housings made of PPS-CF10 can operate stably for long periods in 180°C high-temperature environments and possess high impact strength. When equipment is subjected to collisions or vibrations, they effectively protect the normal operation of internal connectors. Furthermore, their good chemical corrosion resistance allows adaptation to chemical erosion in different environments, improving the reliability and service life of electronic equipment.

3. Aerospace Industry: Small Structural Brackets

In the aerospace field, some small structural brackets need to be lightweight while maintaining high strength and resistance to both high and low temperatures. Small structural brackets made of PPS-CF10 weigh only 50% of traditional aluminum alloy brackets, significantly reducing the overall weight of equipment, which helps reduce energy consumption and improve flight performance. Meanwhile, the brackets maintain stable mechanical properties within a temperature range of -50°C to 200°C, adapting to temperature changes during different flight phases of aerospace equipment. They also exhibit good fatigue resistance, meeting long-term service requirements.

4. Food Processing Industry: Conveyor Equipment Accessories

Conveyor equipment accessories in the food processing industry come into contact with various food raw materials and cleaning fluids, requiring strict corrosion resistance and hygiene performance from materials. Conveyor guide rails made of PPS-CF10 have good acid and alkali resistance, withstanding long-term erosion from cleaning fluids. Their smooth surface prevents bacterial growth, complying with food hygiene standards. Additionally, their excellent wear resistance minimizes wear during long-term use, reducing maintenance and replacement frequency and improving production efficiency.

Engineering Application Value of PPS-CF10

From an engineering application perspective, although PPS-CF10 composites have a relatively high initial purchase cost, they offer high cost-effectiveness when considering their long service life, low maintenance costs, and performance advantages. The material is easy to process and mold, and can be manufactured into components of various complex shapes through processes such as injection molding and compression molding, reducing processing steps and costs.

At the same time, its lightweight property helps reduce equipment energy consumption and operating costs, providing significant advantages in weight-sensitive industries such as automotive and aerospace. Furthermore, the good performance stability of PPS-CF10 helps improve the overall reliability of equipment, reducing downtime caused by component failure and enhancing production efficiency.

In summary, relying on its excellent high-temperature resistance, superior mechanical properties, and good chemical corrosion resistance, PPS-CF10 composites demonstrate unique application value in industries such as automotive, electronic and electrical, aerospace, and food processing. They provide an effective solution for addressing material application challenges under complex working conditions in various sectors and drive technological progress and development in related industrial fields.