Auto Global / JS LIMOUSINE: How to Leverage 3D Printing Technology for Manufacturing Large Automotive Components and Prototypes?

The automotive industry can be considered one of the earliest sectors to adopt 3D printing technology. Forty years ago, the application of 3D printing was referred to as "rapid prototyping." Today, as the industry recognizes the potential of 3D printing for manufacturing, it has once again enthusiastically embraced this technology.

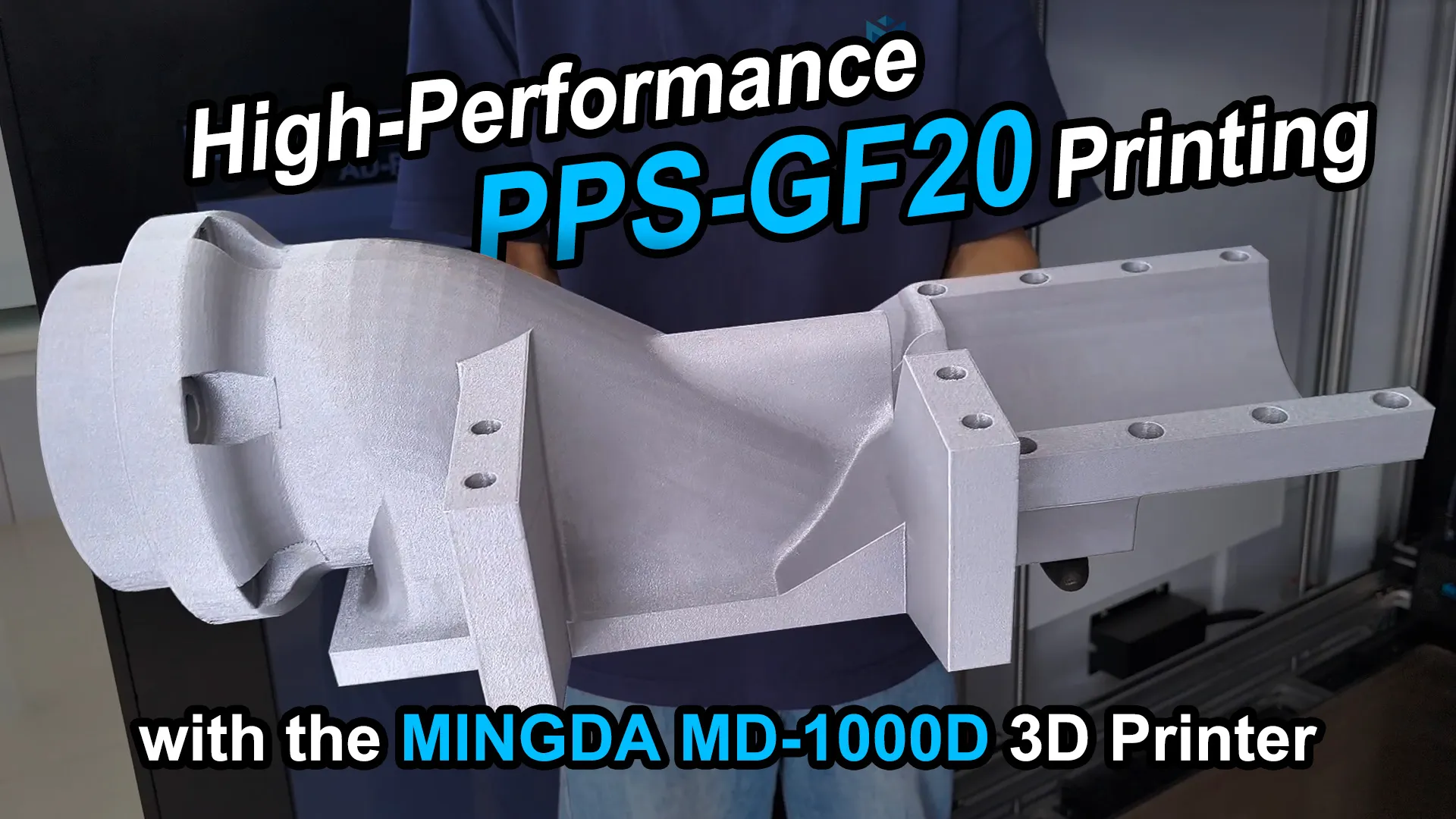

To meet customer demands for lighter and more customized automotive products, JS LIMOUSINE has begun experimenting with 3D printing to produce large automotive components. As a Korean automotive modification company, JS LIMOUSINE is testing MINGDA's 3D printing technology and exploring its potential applications in future vehicle customization, such as performance cars and personalized auto parts. Currently, the company is investigating how to use 3D printing to manufacture large integrated automotive parts, like spoilers, for prototype development and future vehicle manufacturing.

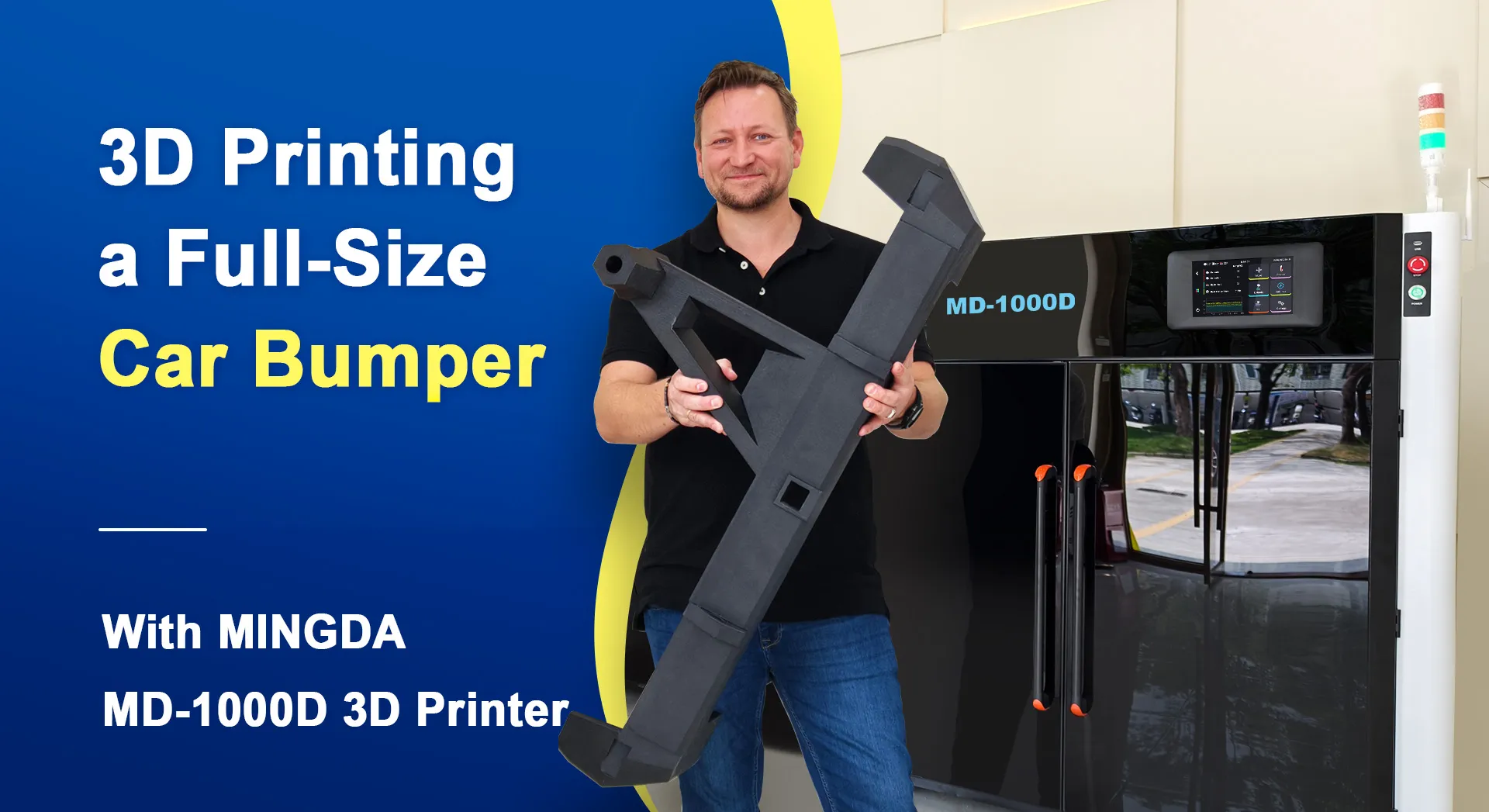

3D-printed large automotive components, such as spoilers, are increasingly advantageous in terms of cost and efficiency, benefiting both manufacturers like Ford and consumers. Compared to traditionally manufactured parts, 3D-printed components are lighter and may contribute to improved fuel efficiency. The MINGDA printing system can produce automotive parts of almost any shape or length, offering a more economical and effective method for manufacturing low-volume molds, prototype components, or custom parts, such as those used in Ford performance models or personalized automotive applications. This technology has the potential to become a groundbreaking advancement in automotive manufacturing.

(Printed Automotive bumper prototype by MD-1000D)

About Auto Global/JS Limousine

Auto Global/JS Limousine Co., Ltd. is an automotive manufacturing company approved by the Korean Ministry of Land, Infrastructure and Transport. Recognized for its advanced technological capabilities and proven project execution, the company was selected as a domestic parts supplier for the Air Force Command's component localization project. Leveraging its demonstrated technical expertise, the company continues to expand its diverse lineup, which includes automotive mechanical design, interior and exterior customization, specialized vehicle manufacturing, and converted models based on Mercedes-Benz RV/SUV/MPV platforms. With a vision to transcend the domestic market, JS Limousine is poised to take on new challenges on the global stage.

Additive Manufacturing Technology

With the increasing efficiency and decreasing costs of 3D printing, many companies are adopting this emerging technology for production applications across various fields such as aerospace, education, and health care. According to data from Global Industry Analysts Inc., recent technological advancements, emerging application areas, and government support have driven the broader adoption of 3D printing. By 2024, the global 3D printing market is projected to reach a value of $25 billion. In the future, 3D printing could bring significant benefits to automotive production, including the manufacturing of lighter-weight components, which may help improve fuel efficiency. For example, a 3D-printed spoiler may weigh less than half of one produced through metal casting.

Additionally, 3D printing technology offers better cost-effectiveness for producing parts with lower demand, such as prototype vehicles and specialized racing components. Ford can also leverage this technology to print larger molds, jigs, and custom parts for customers.

Harry Lee, Head of Manufacturing Research Technology at JS LIMOUSINE, stated, "With MINGDA’s additive manufacturing technology, we can now print large molds, jigs, and components, allowing us greater flexibility in design iterations. We are excited to be among the first to implement MINGDA’s new technology, which helps us advance large-scale printing technology tailored to automotive applications and demands."

(JS LIMOUSINE staffs are receiving training on the MD-1000D)

Applications of 3D Printing Technology in Automotive Manufacturing

Manufacturing Automotive Parts

Manufacturing Complex Cavities in Automotive Molds

The shapes of components produced by modern enterprises are becoming increasingly complex, posing significant challenges to the production of mold cores and cavities during the manufacturing process. For example, when producing automotive air conditioning shells, their intricate external structures necessitate the creation of complex cavities and cores in mold production. Such parts often can only be manufactured using embedded or spliced methods. Traditional manufacturing techniques struggle to achieve high precision in mold production, and the production cycle is significantly extended, making conventional part manufacturing both costly and time-consuming.

By adopting FDM 3D printing technology in the manufacturing of enterprise parts, it is possible to effectively control the complex cavities of automotive molds while achieving integrated processing of these intricate structures. The use of 3D printing technology can reduce production costs, shorten processing time, and improve both cost efficiency and production timelines.

Achieving Light weighting in Automotive Manufacturing

Energy conservation and emissions reduction have always been critical concerns for the automotive industry and transportation sector. Automotive enterprises often prioritize lightweighting as a key goal in their manufacturing processes. To reduce the overall weight of vehicles, it is essential to decrease the weight of individual components. The application of 3D printing technology in the manufacturing of automotive parts enables enterprises to achieve lightweight production. The use of alloy materials to manufacture automotive components makes it possible to achieve results that are difficult to attain with traditional manufacturing methods.

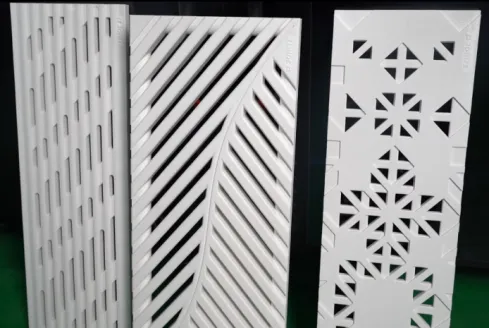

(printed by the MD-1000D, after polishing and painting)

Currently, JS LIMOUSINE uses PLA as the primary material for printing automotive parts. However, to meet the diverse needs of different customers, it is necessary to select different materials and adjust printing parameters accordingly to manufacture corresponding parts. Compared to traditional manufacturing processes, 3D technology offers greater design freedom, as it enables the printing of almost any geometric shape. This allows developers to modify designs based on customers' personalized requirements. In this regard, the MD-1000D fully meets these needs. Harry mentioned that MINGDA 3D helps them explore new materials and optimize more printing parameters. Additionally, Harry stated, "It's different—it pushes us forward."