MINGDA 3D Printing Powers Circuit & Dreams CLR Racecar Showcase at Tokyo Auto Salon

![MINGDA 3D Printing Powers Circuit & Dreams CLR Racecar Showcase at Tokyo Auto Salon]()

In the high-performance automotive and motorsport industry, the demand for large, lightweight, and geometrically complex components is increasing. Traditional manufacturing methods often struggle with intricate surfaces, rapid design iterations, and small-batch production, making it challenging to maintain strength and precision while keeping development cycles short.

1. About Circuit & Dreams CLR

Circuit & Dreams CLR is a Japan-based racing technology team composed of engineers and motorsport enthusiasts. The team specializes in racecar development, modification projects, and custom component manufacturing, offering end-to-end capabilities from design and production to testing.

Team leader Takuro Watanabe frequently shares updates on vehicle tuning and track testing through social media, demonstrating the team’s expertise in both technical development and practical application. Beyond competing in racing events, the team undertakes custom projects from design planning to component production, positioning itself as a leading force in Japan’s racing and automotive modification scene.

2. Manufacturing Challenges

During development, Circuit & Dreams CLR faced several key challenges:

● Complex and large components:

Traditional methods could not easily achieve required precision and strength.

● Small-batch production and fast iteration:

Outsourced workflows were inefficient and slow to respond.

● Frequent design changes:

Conventional tooling and machining could not quickly accommodate modifications.

3. Solution

To address these challenges, the team adopted MINGDA large-format industrial 3D printers, leveraging:

● Segmented printing and structural optimization:

Ensuring strength, dimensional accuracy, and surface quality for large components.

● Rapid iteration:

In-house printing allows quick validation of design changes, accelerating project progress.

● Flexible production:

Reduced reliance on external supply chains, enabling timely adjustments.

● Stable and reliable performance:

Smooth printing processes improve overall manufacturing efficiency.

(Printed Automotive shells prototype by MD-1000D)

4. Project Outcome & Customer Feedback

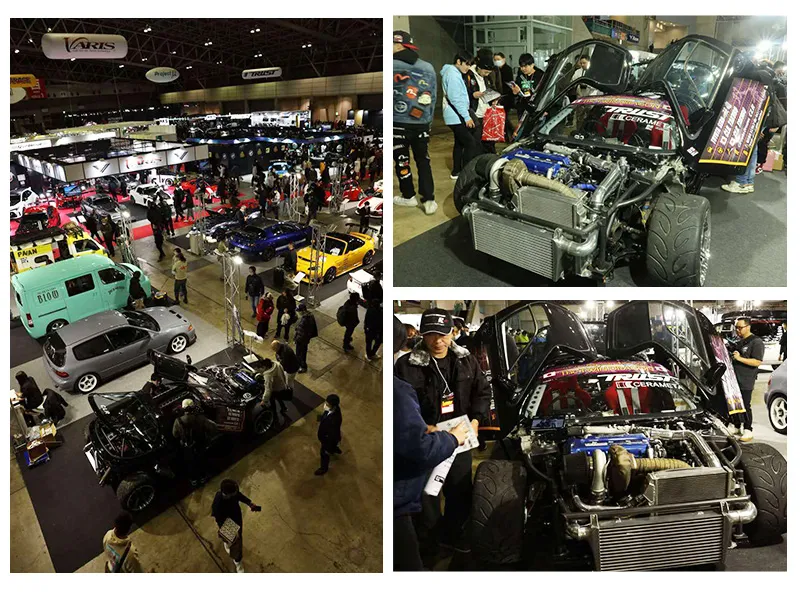

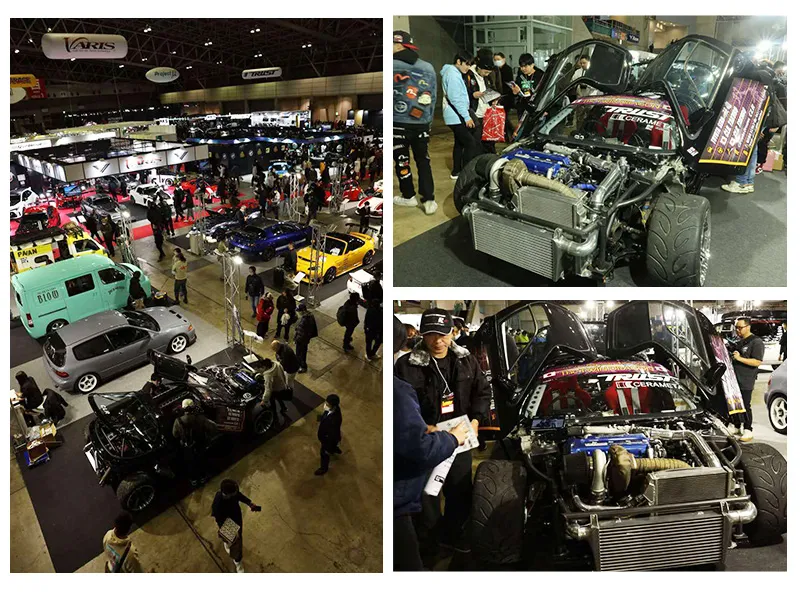

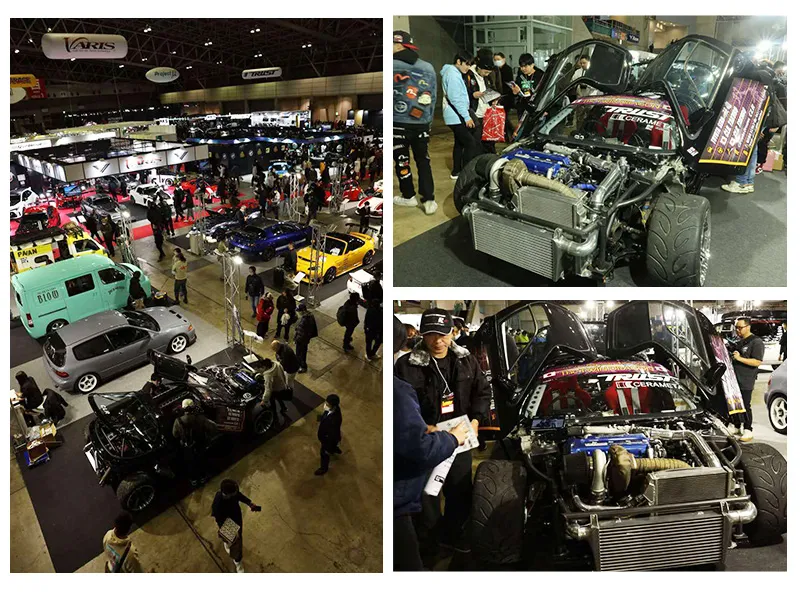

The 3D-printed racing components were successfully integrated into the vehicle, which was showcased at Tokyo Auto Salon, demonstrating innovative design and manufacturing.

(Printed Automotive shells prototype by MD-1000D)

4. Project Outcome & Customer Feedback

The 3D-printed racing components were successfully integrated into the vehicle, which was showcased at Tokyo Auto Salon, demonstrating innovative design and manufacturing.

Takuro Watanabe remarked:

“MINGDA 3D printers performed reliably throughout the project, meeting our requirements for component size, production efficiency, and lead time. They significantly shortened the design-to-physical validation cycle and provided greater flexibility for advancing the vehicle project.”

5. Industry Impact & Future Outlook

This case highlights the potential of MINGDA 3D printing in motorsport and high-performance automotive applications, particularly for rapid production of complex components and small-batch customization. Moving forward, MINGDA will continue collaborating with global partners to expand the use of 3D printing in automotive, racing, and industrial manufacturing, enabling faster design validation and more efficient component production.

Takuro Watanabe remarked:

“MINGDA 3D printers performed reliably throughout the project, meeting our requirements for component size, production efficiency, and lead time. They significantly shortened the design-to-physical validation cycle and provided greater flexibility for advancing the vehicle project.”

5. Industry Impact & Future Outlook

This case highlights the potential of MINGDA 3D printing in motorsport and high-performance automotive applications, particularly for rapid production of complex components and small-batch customization. Moving forward, MINGDA will continue collaborating with global partners to expand the use of 3D printing in automotive, racing, and industrial manufacturing, enabling faster design validation and more efficient component production.