The Advanced Tech Behind Architecture: Why Every Design Studio Needs 3D Printers?

The field of architecture has always embraced innovation, and currently, additive manufacturing is leading this transformative movement. This groundbreaking approach is revolutionizing conventional practices in building design and fabrication, unlocking unprecedented creative potential for design professionals worldwide. So what exactly positions this technology as a revolutionary force in contemporary architecture?

In partnership with MINGDA 3D, Jonite provides fully adaptable design solutions engineered for diverse settings and uses, enabling the designers to materialize more ambitious and inventive structural concepts.

About JONITE

Jonite is a Drainage Systems and Grates Manufacturer, with over 25 years of experience, it is professional in hardscape design. Since 1994, many clients have specified our reinforced decorative stone gratings for their beauty and unparalleled load-bearing performance, bringing their transformational design visions to life. They are writing a new design narrative that combines sustainability and unparalleled design freedom.

What process was used before 3D printing? Explain this process and its challenges.

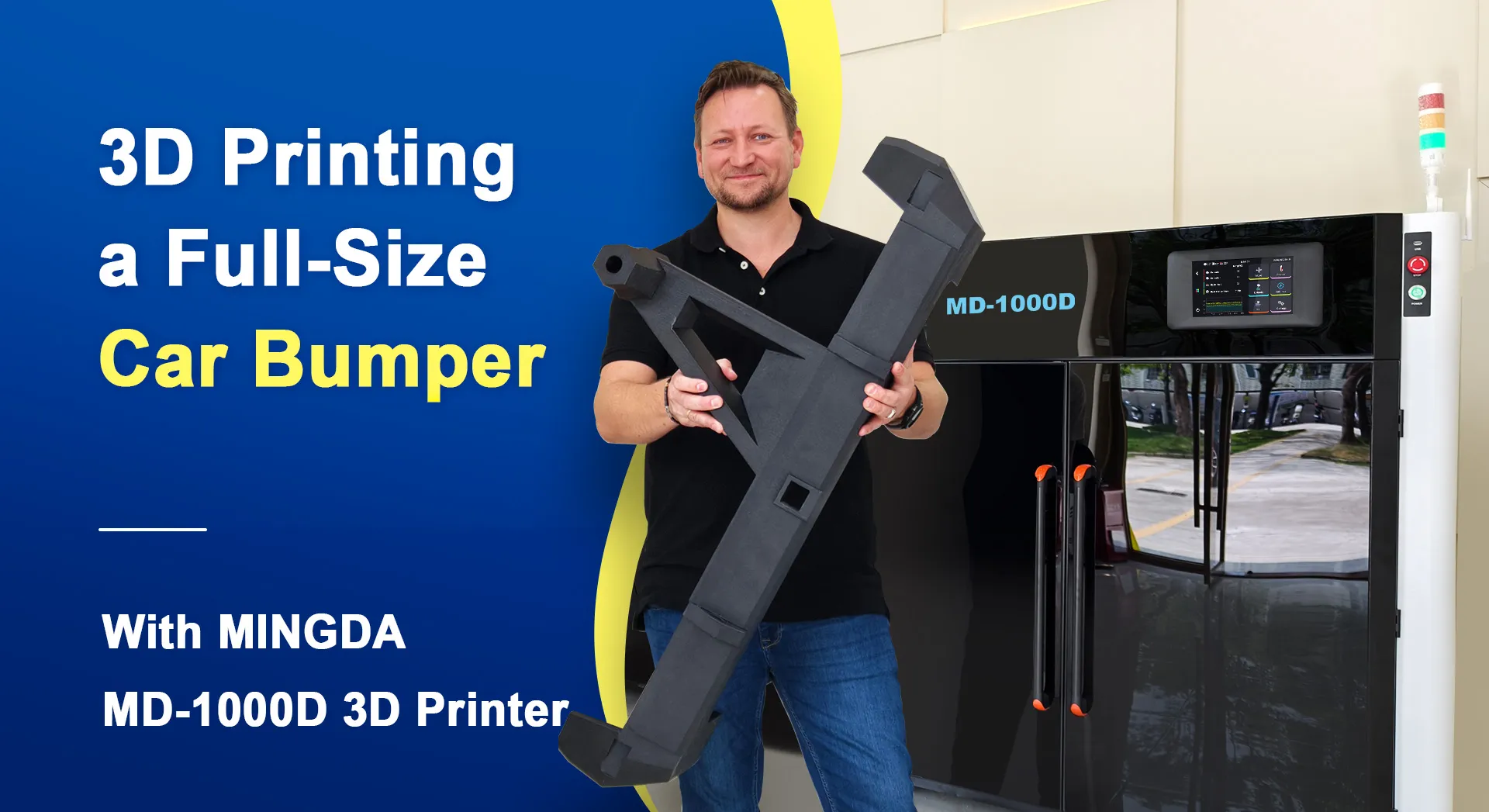

Mr. Daniel, the designer of Jonite noted that previously, the company relied on Third-party service providers to produce 3D models—a process that was not only expensive but also time-consuming, often requiring one to two weeks for completion. Due to these constraints, 3D modeling was utilized sparingly. However, since acquiring the MD-1000D 3D printer for in-house use, the team has significantly expanded its applications for 3D models while drastically reducing production time. What once took weeks can now be accomplished in a matter of hours.

According to another designer, Mr. Lambert, 3d printing has now been integrated into Jonite’s work-flow as a standard procedure. This advancement allows the company to rapidly generate prototype design samples for client review—a capability that has been met with enthusiastic feedback. “Clients appreciate how this technology simplifies the visualization of our design intent,” Daniel added.

Large Scale Printing Creates Unique Design Possibilities

While 3d printing was historically employed by industrial firms for component fabrication, Jonite emerged as an innovator by adopting this technology as its core production methodology for complete end-to-end product manufacturing.

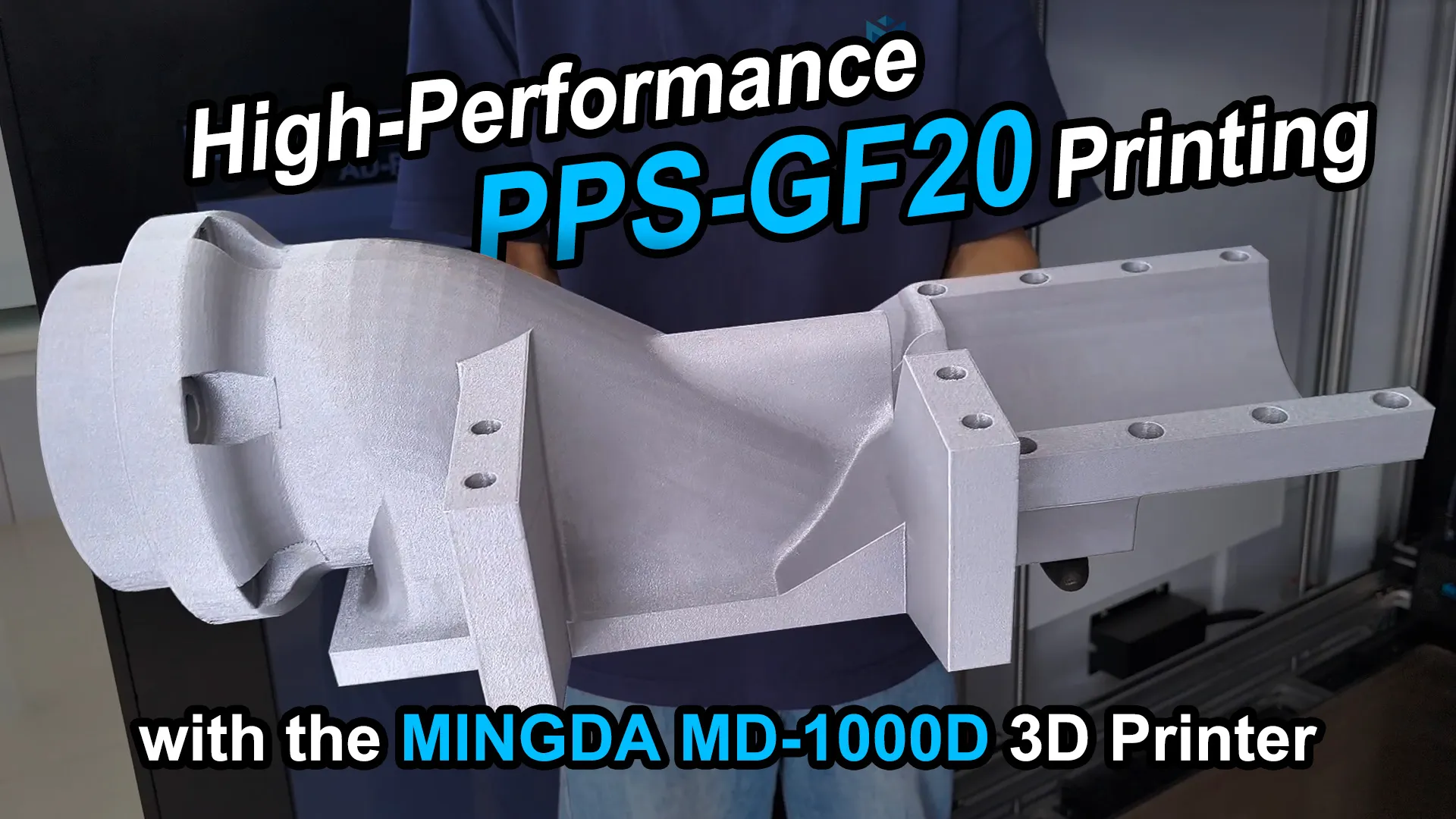

The capacity to fabricate monolithic structures – including drainage grates and covers – using industrial-grade printer like the MINGDA MD-1000D has allowed Jonite to establish specialized design competencies. These manufactured solutions demonstrate exceptional structural integrity, longevity, and distinctive aesthetic characteristics.

"Industrial-scale additive manufacturing has fundamentally enhanced our capacity for innovative design realization," Daniel elaborates. "MINGDA's advanced printing systems serve as pivotal enablers, dramatically compressing production timelines while maintaining cost efficiency to facilitate unprecedented design exploration."

3D Printing in a Circular Economy

Product design and construction industries have been plagued by non-sustainable practices, especially with non-recyclable plastics and other materials. But Jonite is proving that 3D printed products have earned their place within the circular economy with their choice of materials.

With MINGDA’s user friendly slicing software, Jonite can select the appropriate materials according to the requirements of each design, and set up printing parameters for each geometric model.

In addition to citing MINGDA’s PETG-HF filament as exceptional with regards to their material composition and heat resistance qualities, Daniel also emphasized the importance of eco-friendly and recyclable in the company's philosophy.

Enhanced Aesthetic Appeal and Streamlined Post-Production Process

Jonite has strategically integrated MINGDA 3D printers, specifically the high-precision 1000D model, into its production workflow. "After the comprehensive market evaluations, MINGDA emerged as the clear leader in terms of cost-performance," the company states. "This investment is projected to recoup its costs within approximately 12 months of operation."

The independent dual-extruder (IDEX) configuration can print with double extruder, delivering both enhanced visual dimensionality and significant post-processing efficiencies. "Dual-color capability is operationally critical for our workflow," explains Jonite's technical team. "When incorporating brand elements like client logos into components, the ability to print multiple colors in a same model eliminates numerous secondary finishing steps, dramatically improving production efficiency."

Future-Oriented 3D Printing Applications in Our Industry

Mr. Lambert and Mr. Daniel highlight that while their current 3d printing applications primarily serve prototyping purposes, the organization is actively pursuing innovative material solutions to transition toward functional end-use production. Specifically, they focused on searching advanced composite filaments capable of replicating the authentic tactile properties of natural stone while incorporating superior environmental resilience—including UV stability, thermal endurance, and moisture resistance—to enable direct outdoor deployment of 3D-printed architectural elements.